Background

A medium sized company had achieved rapid growth via acquisition, but the facilities across the US had vastly different performance. The client wanted to optimize operations to increase capacity by at least 30% with existing space and equipment. The company had some high-volume, standard products, but much of the business was custom and seasonal.

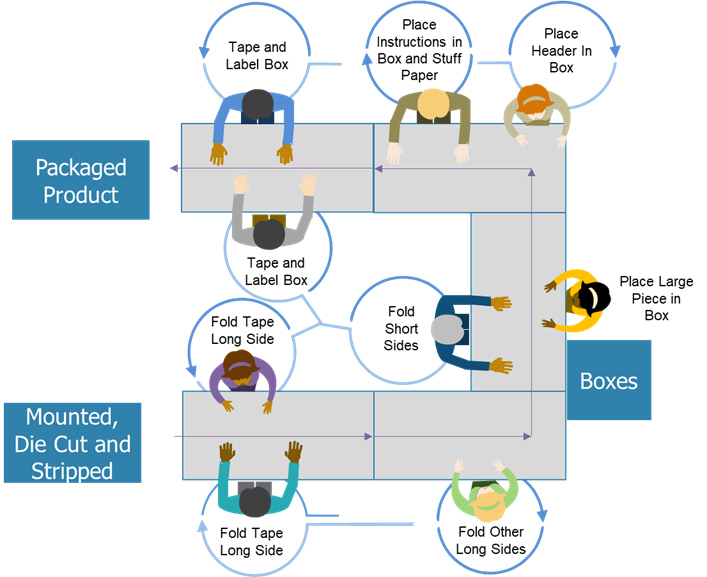

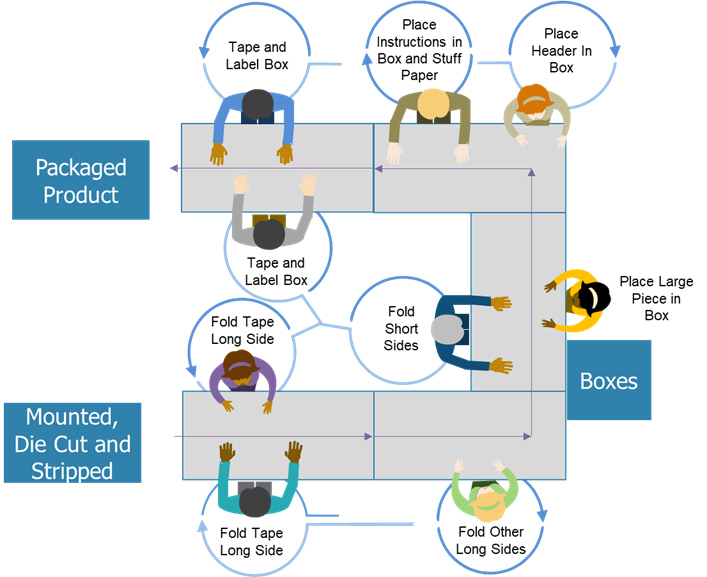

New U shaped design with process balancing improved flow and efficiency.

Solution

Firefly was asked to optimize and execute a Lean transformation focusing on their bottleneck areas: kitting and fulfillment. Application of 5S increased operations space from 20,000 to 35,000 square feet, and processes were optimized to create flow through the building. Communication was improved with structured, daily production meetings to identify new jobs, issues, and actual production that affected the schedule. The management team was trained in Lean tools and techniques to sustain the improvements, including cellular design and process balancing, to further increase capacity and minimize WIP. The team re-aligned management to become accountable for their own operations areas, and consolidate support services such as receiving, shipping, and material handling. The Lean transformation included both a training component and the development of a playbook, so that the client personnel would be able to re-lay out the cells, as needed when new, custom products hit the schedule. We worked in partnership with the client throughout the project, so that the leadership would be able to implement key learnings at additional locations.

Results

As a result of the Lean implementation, kitting and fulfillment space was increased 40% and capacity was increased by 75%. The building has become a cleaner, more productive, and safer place to produce customer orders. It is being sustained with better scheduling, staff education, and audits. Teamwork has improved as there is now clearer alignment with the daily work and higher-level goals and objectives.

Want to see results like this at your company? Contact our team to learn more.