Our experience includes large high-volume manufacturers, smaller job shops, mid-market companies, and turnarounds with private equity ownership. We’ve also worked extensively in warehousing and distribution. Industries include automotive, aerospace, defense, chemicals, packaging, oil and gas, paper, consumer packaged goods, pharmaceuticals, medical products, and construction.

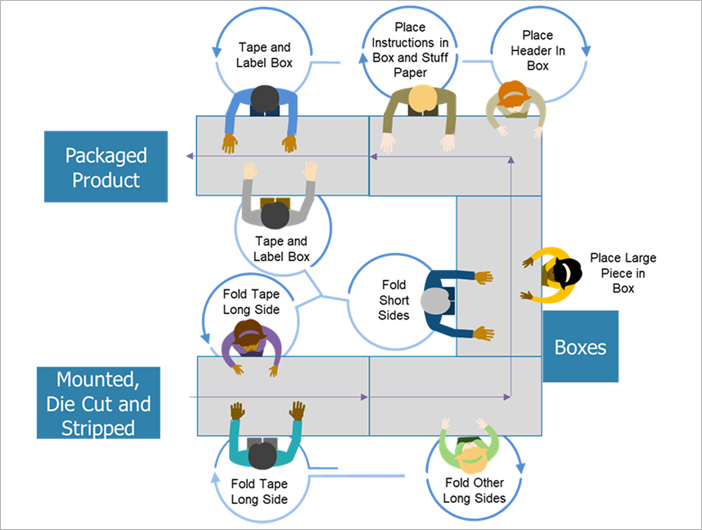

Typical consulting projects include capacity improvements, cost reductions, quality improvements, efficiency increases, and helping companies scale for growth. We often begin with an assessment, to identify the most impactful opportunities. Additionally, we offer training programs to develop internal capability, including Lean, Kaizen Leader, and Lean Six Sigma.

Sample Client Results

- Manufacturing – 40% reduction in cycle time. Developed new quality strategy.

- Supply Chain – 50% increase in capacity. 20X ROI Lean Six Sigma program.

- Order Fulfillment – On-time deliveries, during peak season, improved dramatically from 19% to 95%.

- Assessment – $300M inventory reduction opportunity. 25% reduction in time-to-market for new products.

Contact our team to discuss your next business improvement project.